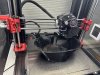

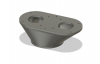

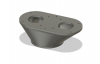

In one of my mounting locations, a single Z12 is about to gain a partner to improved simultaneous vehicle, surroundings, and license plate capture. Currently, a single camera junction box is in that location. It is Tap Conn'ed into cement and I was not wanting to drill more holes to add another junction box to mount the 2nd camera. Instead, I modeled up a dual mount that will fit atop the existing junction box. The riser portion will bolt onto the standard round junction box. The top, flat cover will have both cameras bolted to it and then it will go atop the funner shaped riser.

Here are picts of the model and a video of the riser being 3D printing in PETG. I have used a PETG mount for two turrets atop a camera pole. That has held up well despite all sorts of weather.

The top cover of this new mount design took just over 8 hours to print. The funnel is going to be over 24 hours of print time.

You will notice the riser is not symmetric. The two cameras are offset unequally from center to better clear a nearby pillar.

View attachment mount printing.mp4

Here are picts of the model and a video of the riser being 3D printing in PETG. I have used a PETG mount for two turrets atop a camera pole. That has held up well despite all sorts of weather.

The top cover of this new mount design took just over 8 hours to print. The funnel is going to be over 24 hours of print time.

You will notice the riser is not symmetric. The two cameras are offset unequally from center to better clear a nearby pillar.

View attachment mount printing.mp4