I am curious about your expert views on the way how Dahua cams (and probably many others) are mounted, especially in combination with a junction box.

First of all, I had no previous experience with CCTV/IP cams and their installation. So, some of the following statements and observations may seem obvious or naive.

I am now operating 4 Dahua-based cams and 1 more to come. 3 out of 4 are turret cams that are combined with a PFA130-E junction box. The turrets are mounted upside down at the wooden parts underneath the roof (overhang). I had to get completely new cables from the rack in the basement to those spots. When I planned the camera project, I did not know how to get the cables into the camera itself respectively how the connection physically works out. So I ordered the cameras first and then thought about the next steps.

When the cameras arrived, I was surprised about the fixed mounted, and fixed length pigtail. I was expecting a more modular approach, which would allow for more flexibility. Bottom line: I needed some kind of junction box although I knew this would made the overall appearance of the camera even larger.

My observation:

What is best practice to connect cable and pigtail?

Looking forward reading you comments.

Chris

First of all, I had no previous experience with CCTV/IP cams and their installation. So, some of the following statements and observations may seem obvious or naive.

I am now operating 4 Dahua-based cams and 1 more to come. 3 out of 4 are turret cams that are combined with a PFA130-E junction box. The turrets are mounted upside down at the wooden parts underneath the roof (overhang). I had to get completely new cables from the rack in the basement to those spots. When I planned the camera project, I did not know how to get the cables into the camera itself respectively how the connection physically works out. So I ordered the cameras first and then thought about the next steps.

When the cameras arrived, I was surprised about the fixed mounted, and fixed length pigtail. I was expecting a more modular approach, which would allow for more flexibility. Bottom line: I needed some kind of junction box although I knew this would made the overall appearance of the camera even larger.

My observation:

- The quality of the junction box is rather good, especially with the torx screws. Good first impression.

- The box seems huge but getting the pigtail and the network cable in, is very tricky

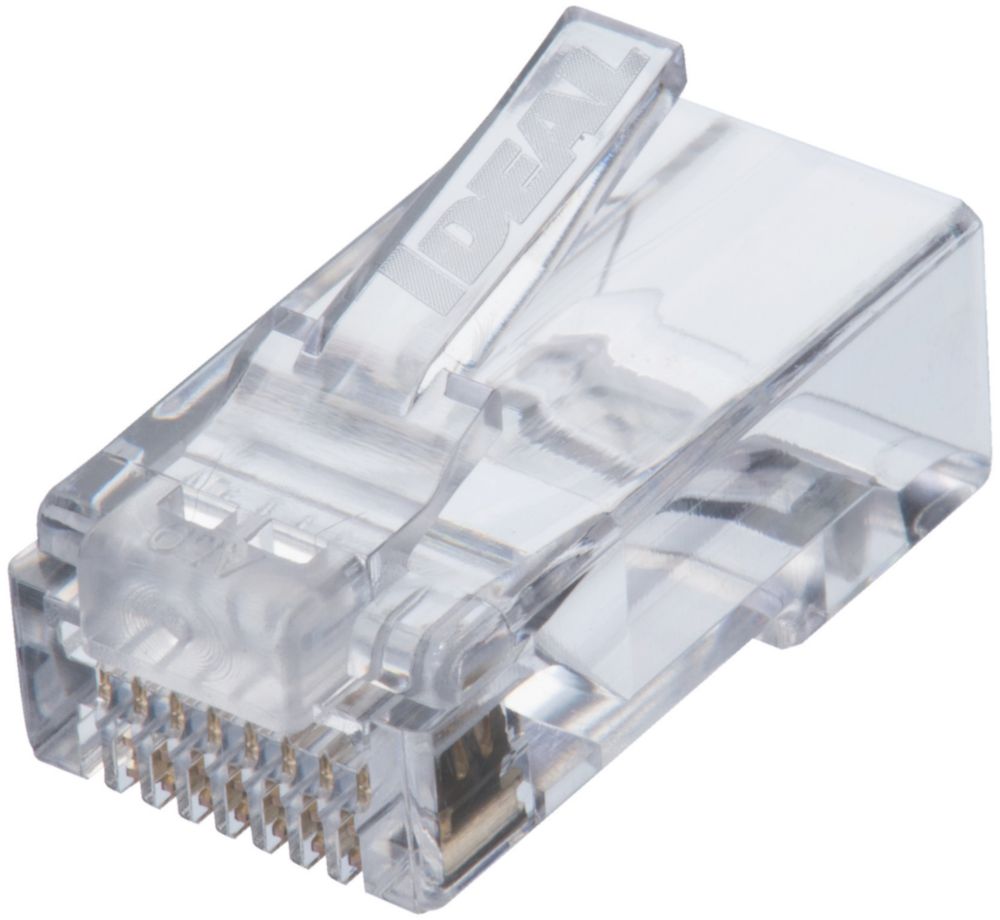

- I can hardly fit the combination of RJ45 connector of the cable attached to the pigtail in that box without torturing the cables a bit (both attached together are actually too long). => What is best way to attach cable and pigtail and not running into that problem?

- Mounting the camera to the junction box with only two hands is somewhat impossible as there seems to be a design flaw with the mounting (at least with the larger turret cams): There is a lid attached to the box (hold with a metal cable if screws are not fixed). Potentially this should be able to hold the lid PLUS an attached camera. However, it is not possible to mount the camera to the lid as the lid needs to go first to the box. As a result, you need to mount the lid and then the basis of the camera to the lid, while holding the eye ball of the camera in a third hand as the pig tail already needs to be connected to the cable in the box. After that it is required to get the remaining pig tail cable into the box while holding the eye ball and fixating the rubber seal at the same time. Installation Nightmare

- A G3/4 screw thread is pretty much non-standard outside the imperial world. In Germany, you would use it only for plumbing but not in electrical installations

What is best practice to connect cable and pigtail?

Looking forward reading you comments.

Chris

that looks bulletproof.

that looks bulletproof.