Being the obstinate old codger I am, I wanted to be able to activate a normal, coil based, doorbell with the VTO2202F. So I did a little hack to make that possible.

I opened up the case of the VTO hoping to "piggy back" another microswitch some how, but that doesn't seem very practical once I had a look at the inside and how it's built. So the next thing to try was to see if I could pick off the existing button. I assumed one side of the button would go low when the button is pressed. Since it's inside the case and there's that pesky tamper switch, I tacked a short lead onto each leg of the switch on one side. I used a Hako solder station and would suggest not to try this with an non temperature controlled soldering iron. It needs good temperature control and a fine tip to make sure nothing else happens. There's enough space around the RJ45 connector to let these leads come back out of the case without drilling any holes.

My thought was to use an inexpensive opto coupler to take the switch "low" signal and use the coupler to fire a relay for the doorbell. Once I put the VTO back together I connected a DVM to ground, conveniently located on the extreme left of the connection block on the left, and checked each lead for ground when the button was pushed. Sure enough, one side went low. The black wire in the photos. That black wire connects to the input terminal on the opto coupler and the ground connects to the minus power connection for the opto coupler. Press the button and the relay fires. Now I can get a regular doorbell to work with the VTO with just an additional pair of wires.

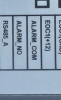

Here's a shot of the back of the VTO before disassembly. The screws are the standard Torx size used for Dahua turret cameras. You can also see the ground connection listed on the label on the extreme left end -

Here's the assembled VTO once the cover is off. It is necessary to remove four Phillips head screws so the other side of the lower board, where the switch is, can be accessed -

Here's a shot with the board flipped up to get to the switch. Be careful not to over flex the ribbon cable that connects to the camera board -

Here's the switch we're interested in -

Here are the two leads I attached. The only one needed is the black lead on the left side of the switch in this view -

As you can see, soldering on is a little touchy even with a temperature controlled iron.

I used this opto coupler. It has an input impedance in the megaohm range to keep loading the VTO to the bare minimum -

One more thing I did is add a .1uf/600VDC capacitor across the NO relay contacts to keep arcing to a minimum to extend the life of the relay contacts. I'm powering it with a USB wall wart, 5VDC.

As with everything, proceed with caution and no guarantee is expressed or implied. YMMV

I opened up the case of the VTO hoping to "piggy back" another microswitch some how, but that doesn't seem very practical once I had a look at the inside and how it's built. So the next thing to try was to see if I could pick off the existing button. I assumed one side of the button would go low when the button is pressed. Since it's inside the case and there's that pesky tamper switch, I tacked a short lead onto each leg of the switch on one side. I used a Hako solder station and would suggest not to try this with an non temperature controlled soldering iron. It needs good temperature control and a fine tip to make sure nothing else happens. There's enough space around the RJ45 connector to let these leads come back out of the case without drilling any holes.

My thought was to use an inexpensive opto coupler to take the switch "low" signal and use the coupler to fire a relay for the doorbell. Once I put the VTO back together I connected a DVM to ground, conveniently located on the extreme left of the connection block on the left, and checked each lead for ground when the button was pushed. Sure enough, one side went low. The black wire in the photos. That black wire connects to the input terminal on the opto coupler and the ground connects to the minus power connection for the opto coupler. Press the button and the relay fires. Now I can get a regular doorbell to work with the VTO with just an additional pair of wires.

Here's a shot of the back of the VTO before disassembly. The screws are the standard Torx size used for Dahua turret cameras. You can also see the ground connection listed on the label on the extreme left end -

Here's the assembled VTO once the cover is off. It is necessary to remove four Phillips head screws so the other side of the lower board, where the switch is, can be accessed -

Here's a shot with the board flipped up to get to the switch. Be careful not to over flex the ribbon cable that connects to the camera board -

Here's the switch we're interested in -

Here are the two leads I attached. The only one needed is the black lead on the left side of the switch in this view -

As you can see, soldering on is a little touchy even with a temperature controlled iron.

I used this opto coupler. It has an input impedance in the megaohm range to keep loading the VTO to the bare minimum -

One more thing I did is add a .1uf/600VDC capacitor across the NO relay contacts to keep arcing to a minimum to extend the life of the relay contacts. I'm powering it with a USB wall wart, 5VDC.

As with everything, proceed with caution and no guarantee is expressed or implied. YMMV

As an Amazon Associate IPCamTalk earns from qualifying purchases.